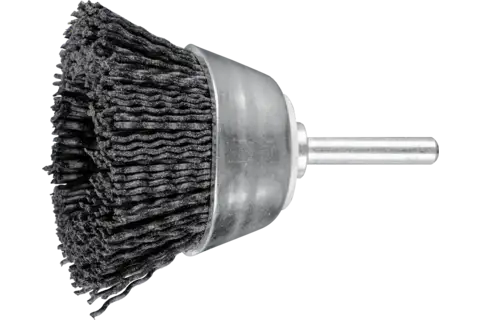

Cup brushes crimped shank-mounted

Cup brush crimped TBU dia. 50 mm shank dia. 6 mm ceramic filament dia. 1.10 mm grit 120

Technical information

Cup brush crimped TBU dia. 50 mm shank dia. 6 mm ceramic filament dia. 1.10 mm grit 120

- Dia. external

- 50 mm

- Dia. filament material

- 1.1 mm

- Dia. shank

- 6 mm

- Filament material

- Ceramic oxide grain (CO)

- Grit size

- 120

- Length, filament

- 22 mm

- Length, total

- 75 mm

- Max. RPM

- 10500 RPM

- Mounting system

- Shank

- RPM, optimum, from

- 4200 RPM

- RPM, optimum, to

- 6800 RPM

- Width

- 15 mm

- Packaging unit

- 10 pieces

Description

Advantages

Recommendations for use

Safety notes

- Materials that can be worked

- Applications

- Drive types