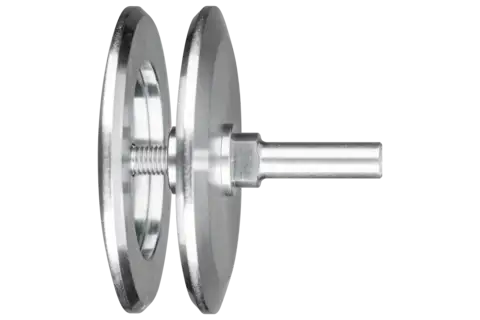

Wheel brushes crimped Composite, with hole

COMPOSITE wheel brush RBUP dia. 200x13x50.8 mm hole ceramic filament dia. 1.10 mm grit 80 stationary

Matching accessories & spare parts

Technical information

COMPOSITE wheel brush RBUP dia. 200x13x50.8 mm hole ceramic filament dia. 1.10 mm grit 80 stationary

- Brush keyways

- 12.7 x 6.4 mm

- Dia. external

- 200 mm

- Dia. filament material

- 1.1 mm

- Dia. hole

- 50.8 mm

- Filament material

- Ceramic oxide grain (CO)

- Grit size

- 80

- Length, filament

- 32 mm

- Max. RPM

- 3600 RPM

- Mounting system

- Centre hole

- RPM, optimum, from

- 900 RPM

- RPM, optimum, to

- 1500 RPM

- Width

- 13 mm

- Packaging unit

- 1 piece

Description

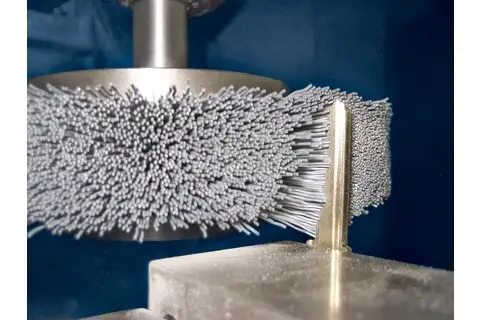

Advantages

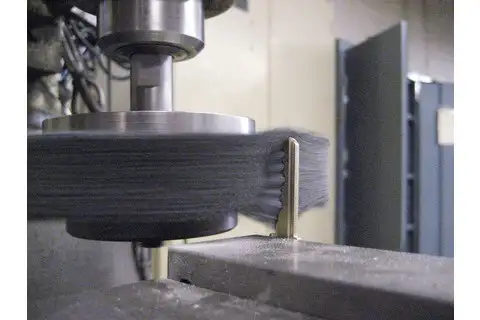

Recommendations for use

Ordering notes

- Materials that can be worked

- Applications

- Drive types

PFERDVALUE

PFERDEFFICIENCY

recommends composite brushes to achieve maximum stock removal as quickly as possible.

PFERDERGONOMICS

recommends composite brushes to sustainably reduce the vibrations produced during use.