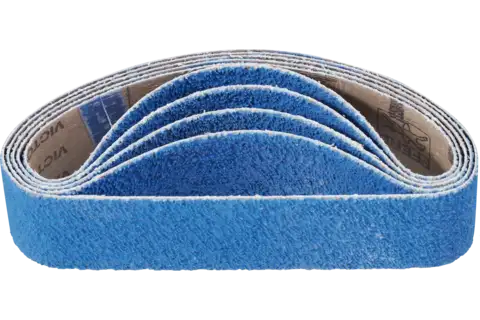

Short belts

VICTOGRAIN-COOL abrasive belt BA 50x450 mm A 36 for extremely high stock removal with a belt grinder

Technical information

VICTOGRAIN-COOL abrasive belt BA 50x450 mm A 36 for extremely high stock removal with a belt grinder

- Abrasive

- VICTOGRAIN-COOL

- Grit size

- 36

- Length

- 450 mm

- Width

- 50 mm

- Packaging unit

- 10 pieces

Description

Advantages

Recommendations for use

Safety notes

- Materials that can be worked

- Applications

- Drive types